Nylon Parts

Nylon parts benefit from utilising one of the most common plastics used in the industry, nylon is a flexible material and can be made into pretty much anything. Nylon parts are commonplace hence you are likely to be in close proximity to a nylon part right now; the uses for the material are extensive.

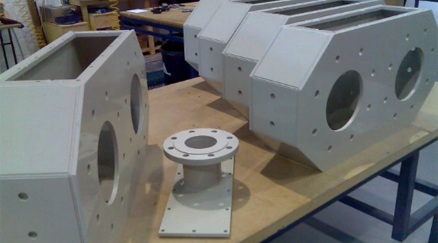

The two common grades of nylon are Nylon 6 and Nylon 6/6 {more choices are available), and these can be transformed to everything from nuts, bolts, bearings and cable ties, as well as going on to be used in personal care products and sports equipment. The sheer adaptability of nylon parts makes them a viable choice for a wide range of applications.

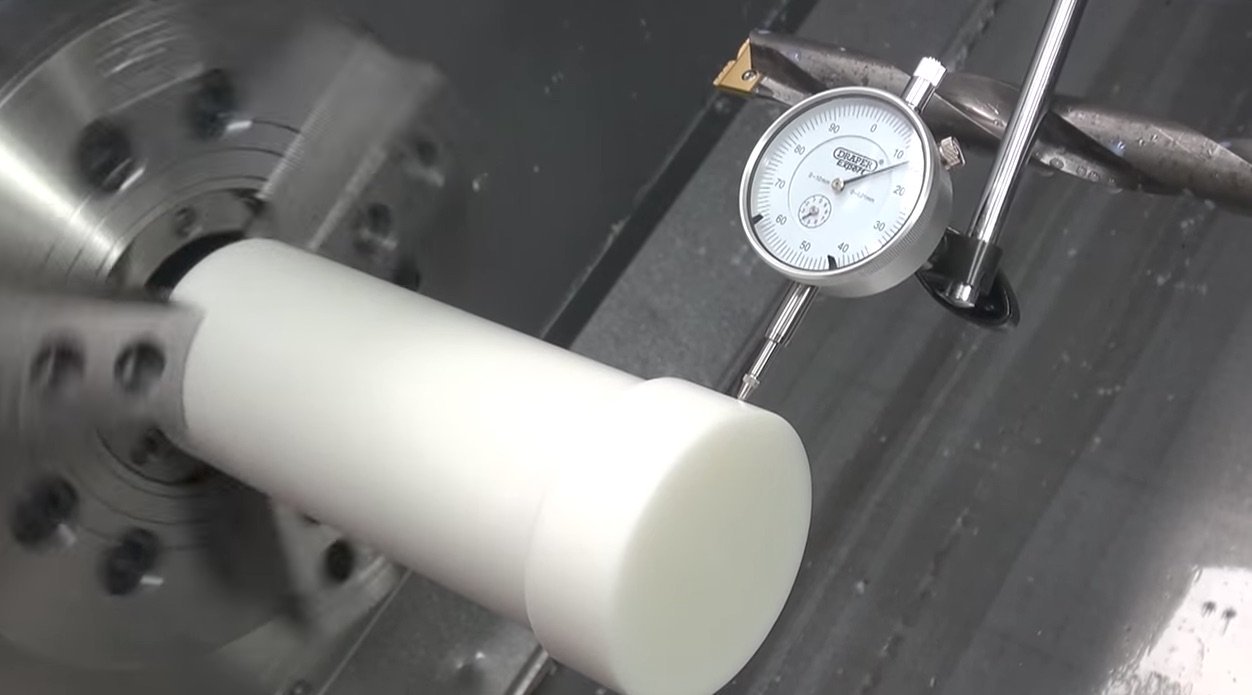

There are many advantages to using nylon parts for various scenarios. Nylon parts are low in cost and be precisely engineered to meet tight tolerances, as well as being highly versatile. Nylon is hard wearing and is highly resistant to corrosion, abrasion and other external contaminants. Nylon parts are lightweight yet tough, as well as being easy to machine, mould or cast making it an ideal manufacturing material. Nylon is used widely across the globe and can be a great substitute for metal parts with added advantages including the ability to resist distortion at high temperatures, the durability to withstand contact with many chemicals and has a high impact resistance, thus making it useful for many heavy duty applications.

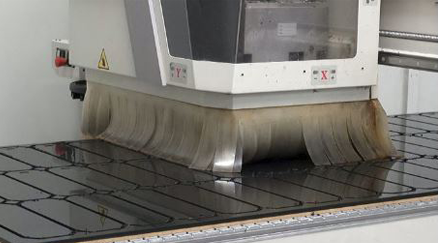

Nylon parts can come in custom shapes with no cost disadvantage due to the ease of manufacturing. The nylon parts are manufactured in a completely controlled environment and is readily available in custom sizes of rod, sheets and tubular bar, for which a large selection of tooling is all ready to be manufactured into your parts. Nylon parts typically are an off-white colour but are commonly available in black and white. Should you require a custom colour for your application; the material can be dyed into virtually any colour, making the possibilities potentially endless. The CNC process allows for easy prototyping of custom nylon parts using CAD software, making it even easier to determine whether your required part is possible.